The Phantom Series racing sim cockpits are as strong as they look. Built using industrial 15 series aluminum profiles, we took the standard sim cockpit and elevated every detail to maximize strength and increase adjustibility.

The Powder Coated Difference

Application:

Powder coating involves applying dry powder to metal surfaces using an electrostatic charge, creating an even coating.

Curing:

After application, the coated metal is baked in an oven to melt and fuse the powder into a durable protective layer.

Durable:

Powder coatings are tough and less likely to chip, crack, or peel compared to other coatings.

Environmentally Friendly:

It produces minimal environmental impact, with fewer volatile organic compounds and no solvents.

The Phantom Line Up

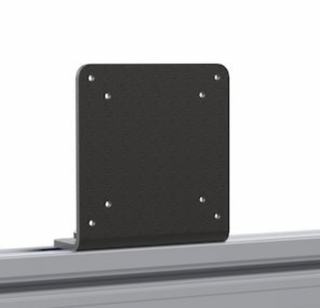

16 Bolts

Secure each Wheel Upright to the cockpit.

4 Bolts

Secure each side wheel mount to the Wheel Uprights.

7 Bolts

Secure each side of the Pedal Plate to the Cockpit.

More Bolts = Stronger Racing Simulator.

Load Capacity

Distributing the load across more bolts increases the overall load capacity of the joint. Each bolt contributes to the joint's ability to withstand forces and stresses.

Improved Stability

More bolts provide additional points of connection, which can enhance the stability of the joint. This is particularly important in applications where the plates may experience dynamic loads or vibrations.

Redundancy

Having multiple bolts creates redundancy in the joint. If one bolt were to fail, the others can still provide support and prevent a complete failure of the joint.

Uniform Stress Distribution

A greater number of bolts can help in achieving a more uniform distribution of stress across the joint. This can reduce the risk of localized stress concentrations that might lead to failure.

Reduced Shear and Tensile Stresses

More bolts can help in distributing shear and tensile stresses more evenly across the joint. This is particularly important in situations where the joint is subjected to forces acting in different directions. Like sim racing wheelbases.

Increased Rigidity

Additional bolts contribute to the overall rigidity of the joint, making it less prone to deformation or misalignment. This is important in applications where precise alignment is crucial.

Improved Resistance to Fatigue

When a joint is subjected to repeated loading and unloading cycles, known as fatigue, the use of more bolts can increase the joint's resistance to fatigue failure.

Enhanced Sealing and Clamping

In applications where a tight seal or clamping force is required, more bolts can help in achieving a more uniform distribution of pressure, improving the effectiveness of the seal.

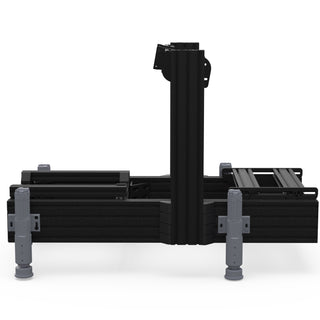

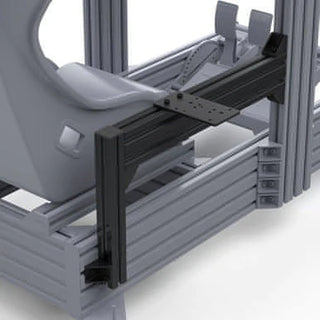

Wheel Upright Mounting

We secured the wheel uprights with aluminum corner brackets instead of the traditional "sandwich plate" which increases the joint strength by sharing the load throughout more high grade 12.9 socket cap head bolts.

360 DEGREES OF FREEDOM.

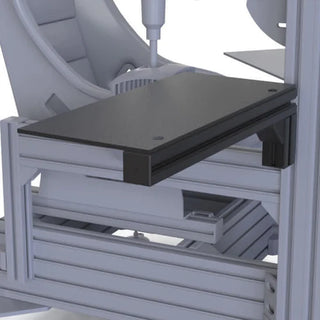

The World's Most Advanced Pedal Mounting System.

Angle it. Raise it. Lower it. Invert it.

Flexibility without Flex.

Angle your wheelbase, bring it forward, push it back. We have you covered.